Degasification involves the removal of dissolved gases from water or aqueous solutions. This process is most commonly used for removing oxygen, carbon dioxide, and nitrogen from water. It involves pumping water through a degasification tower, which is configured with trays or packing to maximize surface area exposure. The pressure of the water flow is reduced for better gas removal.

Degassing Process Equipment

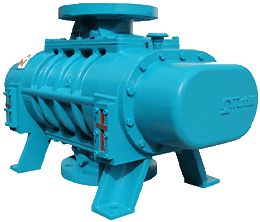

Kinney Liquid Ring Pumps

Two-Stage KLRC – Ideally suited for pumping wet mixtures, including slugs of liquid. 77 – 900 CFM, 4 Torr (5.3 mbar a)

Single-Stage A Series – Unique design allows pump to operate flooded, without damage. 5 – 295 CFM, 25 Torr (33 mbar a)

Kinney Rotary Screw Dry Pump

Dry Screw KDP – Screw-type dry vacuum pump designed to handle process by-products: liquids, condensate and small particles. 88 – 459 CFM, 0.1 Torr (.13 mbar) KDP800 reaches .05 Torr(.06 mbar)

Dry Screw SDV – Screw-type dry vacuum pump with patented variable pitch rotor design commonly used in chemical and pharmaceutical processing. 71 – 441 CFM, 0.01 Torr (0.013 mbar)

Kinney Rotary Screw Dry Pump

PD Plus Blowers 3200 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

PD Plus Blowers 4000 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

PD Plus Blowers 5500 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

PD Plus Blowers 7000 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

PD Plus Blowers 9000 – Up to 15 PSIG (1.03 bar g) pressure boost or 15” Hg (-500 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

PD Plus Blowers 1200 – Up to 15 PSIG (1.03 bar g) pressure boost or 15” Hg (-500 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

Kinney KD & KDH Rotary Piston Pumps

Single-stage, air-cooled and water-cooled duplex rotary piston pumps. 134 – 165 ACFM, 0.01 Torr (0.013 mbar)

Anest Iwata – IPS Dry Scroll

ISP series of vacuum pumps offer a clean vacuum environment and eliminate the nuisance of cumbersome lubricant maintenance or sealing water administration. ISP is free from installation restrictions because of its air-cooled system. ISP maintains low power consumption from atmosphere to maximum pressure. Maximum pressure is 1[Pa] High reliability.

Kinney KVA Rotary Vane Pump

KVA Rotary Vane Vacuum Pump – Most models can achieve ultimate pressure levels near 0.1 mbar (75 microns). Ideally suited for clean or moderately contaminated applications when suction filters are fitted to the pump.

The Gasho team is knowledgeable and experienced in knowing the right vacuum pump to use for specific degasification processes. Questions we typically ask to help us deliver the right degassing solution for your application include:

- What degree of liquid carryover does your degassing process require?

- What types of liquids and gases are you looking to remove?

For assistance in selecting a vacuum pump for your degassing process, contact the specialists at Gasho.

Degassing Industries & Applications

Gasho serves degassing applications used in plant cooling systems in a variety of industries, including power, semiconductor, chemical, and pharmaceutical, steel production, and more.

- Electric Power – Condenser exhausting, water box priming, flue gas desulfurization, fly ash conveying, vacuum deaeration, geothermal gas removal, vacuum pressure impregnation for transformers.

- Chemical Industry – Gas recovery, methane gas recovery, gas boost, petroleum recycle, gas collection, exhaust compression, vapor collection, filtration, de-incineration, exhaust gas recovery, polyester production, PVC production, chlorine packaging – can be used in explosive gas, acid or alkaline gas, or compound gas applications.

- Pulp and Paper – Black liquid evaporation, washing machine of rough pump, lime mud and filter, sediment filter, vacuum dehydrator, degassing system of raw materials and white water, headbox compressor/vacuum pump, suction tank, couch roll, absorption-shift roll and transmission roll, vacuum press, felt suction tank, anti-wind box.

- Mining – Vacuum filtration, multi-effective evaporator, exhaust gas recovery, methane gas extraction, Mine natural gas boost, coal bed methane gas recovery.

- Pharmaceuticals – Drying (tray, rotary, tumble, conical & freeze dryers), reactor drying, distillation, degassing, crystallization/evaporation, filling/transfer material, steam sterilization, deodorization technical in pharmaceutical industry.

- Plastic – Extruder degassing, vacuum forming, vacuum conveying, chloroethylene gas pumping and compressing.

- Environmental – Wastewater treatment, digester gas compression, biogas production, wastewater purification, oxygenation of activated sludge tanks, pond aeration, biogas recovery, wasted processor.

- Food & Beverage – Deaeration of mineral water, deodorizing of edible oils and fats, sterilization of tea and spices, sausage production, ham production, humidification of tobacco, vacuum evaporator.

- Metal Extraction – Steel degassing, vacuum smelting furnace, vacuum heat treatment, Vacuum ion nitriding, vacuum sintering, vacuum melting, vacuum coating, wastewater treatment of steelworks.