Gasho is proud to offer positive displacement rotary blowers from MD-Pneumatics Kinney®, the name known throughout industry for quality vacuum pumps and blowers. Rotary positive displacement blowers combine dependable performance with flexibility. Drop-in replacements are available to fit a variety of applications.

Positive Displacement Rotary Blower Features

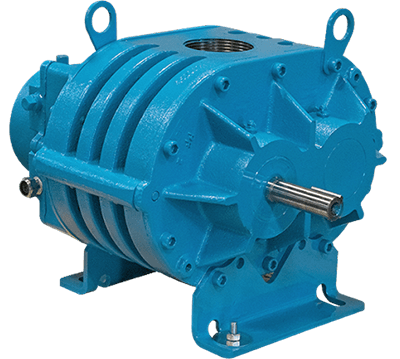

CP Series Blowers

CP Series rotary blowers are designed to be interchangeable with equivalent sizes of competitive models. They are rated up to 15 PSIG discharge pressure or 16” Hg dry vacuum.

Features

- Triple lip seals standard on all models

- Sight glasses standard on all models

- Magnetic drain plugs standard on all models

- Timed with precision helical gears, keyed to the rotor shafts

- Include double-row ball bearings at the gear end

- Rotors with integral shafts

- Reduced noise versions available with tri-lobe rotors

- Bi-directional rotation

- Dual oil splash lubrication at both gear and drive ends available on some models

Typical Applications

- Pneumatic Conveying

- Vacuum Excavation

- Dust Collection

- Carpet Cleaning

- Air Sparging

- Dairy Milking

- Wastewater Aeration

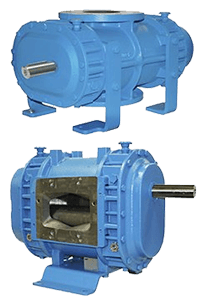

Equalizer Blowers

EQUALIZER DF rotary blowers provide specific advantages such as higher pressure capability (18 PSIG on most models), true, drop-in replacement even to the point of matching the port connector bolt patterns, and helical gearing to reduce noise.

Features

- Compact design

- Bi-directional rotation

- High pressure capability

- Timed with precision helical gears, keyed to the rotor shafts

- One piece housing

- Rotors with integral shafts

- Flow configuration is field convertible from horizontal to vertical

Typical Applications

- Pneumatic Conveying

- Dairy Milking

- Carpet Cleaning

- Compost Aeration

- Dust Collection

- Air Sparging

EQUALIZER RM rotary positive blowers offer many distinct advantages when compared to other brands, such as helical gearing to reduce noise, rotors with integrally cast shafts, positive, locked-in end clearances to prevent internal contact and polished sealing surfaces.

Features

- Compact design

- Available in popular 4.5” and 6” gear diameters

- Bi-directional rotation

- Timed with precision helical gears, keyed to the rotor shafts

- One piece housing

- Rotors with integral shafts

- Flow configuration is field convertible from horizontal to vertical

Typical Applications

- Pneumatic Conveying

- Dairy Milking

- Carpet Cleaning

- Compost Aeration

- Dust Collection

- Air Sparging

PD Plus Blowers

Model 1200 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 15 PSIG pressure boost or 15” Hg dry vacuum (24” Hg water injected).

Model 3200 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 15 PSI pressure or 17” Hg dry vacuum (24” Hg water injected). All models have sight glasses as a standard feature.

Model 4000 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 18 PSI pressure or 17” Hg dry vacuum (24” Hg water injected). All models have sight glasses as a standard feature.

Model 5500 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 18 PSI pressure or 17” Hg dry vacuum (24” Hg water injected).

Model 7000 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 18 PSIG pressure boost or 17” Hg dry vacuum (24” Hg water injected).

Model 9000 PD PLUS heavy duty industrial blowers are designed for high performance applications, up to 15 PSIG pressure boost or 15” Hg dry vacuum (24” Hg water injected).

Typical Applications

- Pneumatic Conveying

- Degassing Process

- Steam Compression

- Vapor Recovery

- Soil Vapor Extraction

- Process Gas Boosting

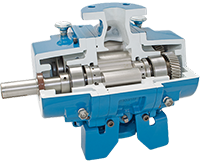

Qx™ Plus Blowers

Qx™ Blowers are high performance, energy efficient blowers that reduce noise while providing long operating life at maximum operating conditions.

Features

- High efficiency at high pressure and vacuum

- Bi-directional rotation

- Timed with precision helical gears, keyed to the rotor shafts

- Includes double ball bearings on timing gear end for additional strength and single roller bearings on drive shaft end of the machine

- L10 bearing life of up to 200,000 hours

- Tri-lobe rotors offer reduced pulsation and lower noise levels

- Oil lubrication on both ends with easy to view sight glasses allowing quick maintenance

- Features larger shaft diameters compared to competing manufacturers

Typical Applications

- Pneumatic Conveying

- Bulk Unloading/Loading

- Wastewater Aeration

- Compost Aeration

- Dust Collection

Positive Displacement Rotary Blower Product Listing

CP Series Blowers (expand)

Equalizer RM Blowers (expand)

Equalizer DF Blowers (expand)

PD Plus (expand)

Ox Blowers (expand)

Gasho will assist you in developing a regenerative blower system that will best meet your specific application needs. Contact us to discuss your project.