Operating an industrial facility with efficiency involves managing a variety of labor, supply chain, and workflow tasks. And when you factor in compliance regulations regarding occupational safety, it can be difficult to balance mandatory OSHA requirements with the most cost-effective business solutions.

Although occupational noise exposure has been regulated by OSHA since the early 70’s, recent changes to those requirements have been enacted. Because serious health problems can result from unprotected exposure to sound, OSHA requires testing, monitoring, and documentation for facilities that consistently experience decibels levels over 85.

Yet, sound enclosures that generate effective controls for industrial noise can solve noise problems and provide your facility with a variety of beneficial advantages.

Not only will you be able to effortlessly meet compliance guidelines, but the overall sound reduction can eliminate some testing and monitoring requirements by OSHA. In addition, lowering the decibels in a facility increases the available work hours per employee, per day, which saves time and money.

Noise Control—Custom Packaged Solutions

No two production facilities, job sites, or industrial locations function the same way. Layouts and space allocation can have huge impacts on decibel measurements, and naturally dictate the type of industrial noise control practices that are required. But, custom sound enclosures offer the simplest solution.

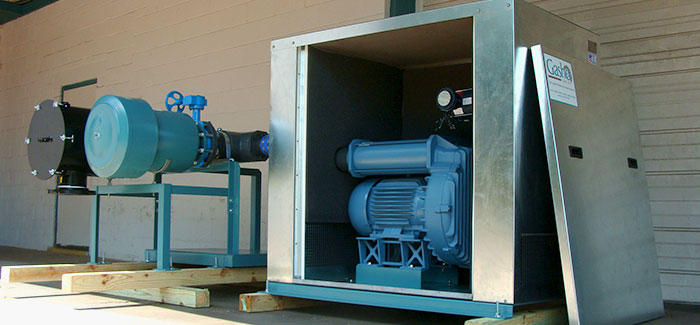

Depending on your specific needs, a qualified supplier like Gasho Inc. can offer custom packaged sound enclosures that control industrial noise at your facility. The most effective models include customizable wall enclosures constructed of metal and enhanced with acoustical reinforcements that absorb sound energy and prevent offensive noise.

Interior Applications with Sound Enclosures

Custom sound enclosures offer maximum flexibility for usage and include:

- Fully removable wall or roof panels

- Passive or forced air ventilation options

- Complete electrical and lighting components

- Full turnkey installation

These enclosures can be utilized to control industrial noise created by a variety of indoor machinery, whether it is produced from a stationary or mobile source. The most common applications feature enclosures for:

- Compressors

- Generators

- Hydraulic equipment

- Industrial fans, grinders, and presses

- Any noisy machinery employed in operation.

Metal sound enclosures are often enhanced with acoustical absorption material when used to reduce the noise that is generated by large milling, presses, grinders or blowers. And they can be constructed as free standing units or utilized with current floor divisionary structures.

The reduced decibel level can help increase employee effectiveness and morale. Moreover, confining the source of the industrial noise will help limit the interference it causes to other electronic equipment and employee floor tasks.

Exterior Noise Management

Many facilities perform operations outdoors, and the subsequent noise generated during operating hours can be less than desirable for neighboring businesses. And although this type of industrial noise may or may not be regulated by OSHA (depending on the definition), it often falls under local ordinance laws.

Sound enclosures or wall panels can be employed to reduce outdoor machinery sounds and control industrial noise from ventilation systems, environmental controls, chillers, blowers, or compressors located outside the facility. This helps insulate your property from costly fines or other imposed penalties.

Benefits and Options

Facilities that employ sound enclosures can expect to achieve:

- Improved productivity

- Reduced OSHA paperwork through compliance excellence

- Custom packaged solutions for sound enclosures that control industrial noise

- Reduced maintenance on equipment caused by sound pollution

To find out more about custom packaged sound enclosures designed to control industrial noise at your facility, speak with a qualified expert at Gasho today. You can also get free consultation assistance on how to fulfill employee training requirements and maintain safe noise levels at your facility from OSHA by requesting a consultation through their Web site.