The problem of wastewater contamination is widespread due to the broad range of industrial processes involving water laced with chemicals, pollutants, harmful bacteria, and other environment-threatening material. While governments have put forth regulatory requirements for reducing wastewater contamination, the responsibility to solve this problem lies with individual businesses and self-regulation. Tuthill provides wastewater treatment solutions that manage contamination and allow clean water to be returned to the environment, while allowing businesses to also remain productive and profitable.

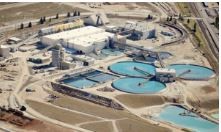

An industrial plant needed an effective solution for the treatment of wastewater. The wastewater from this facility is a by-product of washing the feedstock to remove soil and other materials that contain bacteria. Around 800,000 gallons of wastewater per day is treated to remove these harmful substances. This is achieved by adding microbes to the water that consume and digest the unwanted substances.

The microbes added to the tank need oxygen to survive so the tank must be aerated. Once the water is clean, the water can be released back into the municipal sewer system. The problem for the plant was that the blower packages previously used by the plant were not performing. They were failing the drive motors because the blowers had been undersized. This gave Tuthill an opportunity to provide a solution.

A wastewater treatment system was designed for the plant utilizing Tuthill PD 7013 blowers with a range of 1000 cfm and a pressure range of 14 – 16 psi. The 4 blower packages are located in an outdoor environment and require high operating pressures because of the head pressure from the 2,000,000 gallon storage tank. The Tuthill blowers have provided the necessary performance and continue to operate successfully for the system.

Contact Gasho to learn more and to discuss your project needs.