A wide range of segments is encompassed in the comprehensive chemical processing market. These include basic chemicals such as petrochemicals, plastics, rubber, dyes and pigments, printing inks; specialty chemicals such as paint, adhesives, flavors; as well as agricultural chemicals and consumer products. Tuthill pumps have been used in a wide range of chemical processing facilities around the world for over a century. These vacuum pumps are known for their performance and reliability in harsh and demanding applications.

One example of a Tuthill chemical market application involves the drying and recovery of solvents. A leading supplier in the field of chemical additives and measuring instruments needed a process for recovering solvents used in the production of over 560 additives used in paints, coatings, adhesives, printing inks, plastics, as well as oil and gas exploration. The additives are chemical substances which, when used in small quantities, improve product properties such as scratch resistance or surface gloss. Manufacturing processes are also optimized by the addition of additives.

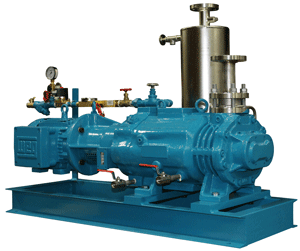

A dependable solution was developed using (5) Tuthill SDV800 / Post Condenser Rotary Screw Dry Pump systems for the drying and recovery. These systems have a vacuum range of 28” – 29.5” Hg. For this particular process, the dry pump allows vapors to pass through the pump and collect at the discharge as they condense. In an oil sealed pump, water vapor or solvent vapor would otherwise mix with the oil and affect pump lubrication.

Tuthill SDV800 / Post Condenser Rotary Screw Dry Pump Features

- Patented variable pitch rotor design increases efficiency and lowers temperatures

- No oil or water in contact with process gases

- Can handle both condensable vapors and some solids without leaving residue

- Capable of full pumping speed from atmospheric pressure to 1 Torr (1.3 mbar a)

- Can achieve ultimate vacuum as low as 0.01 Torr (0.013 mbar a)

- No metal-to-metal contact between operating parts

- Quiet operation

- Niflon coated internals reduce damage from corrosive or condensable gases

Contact Gasho to learn more and to discuss your project needs.